Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

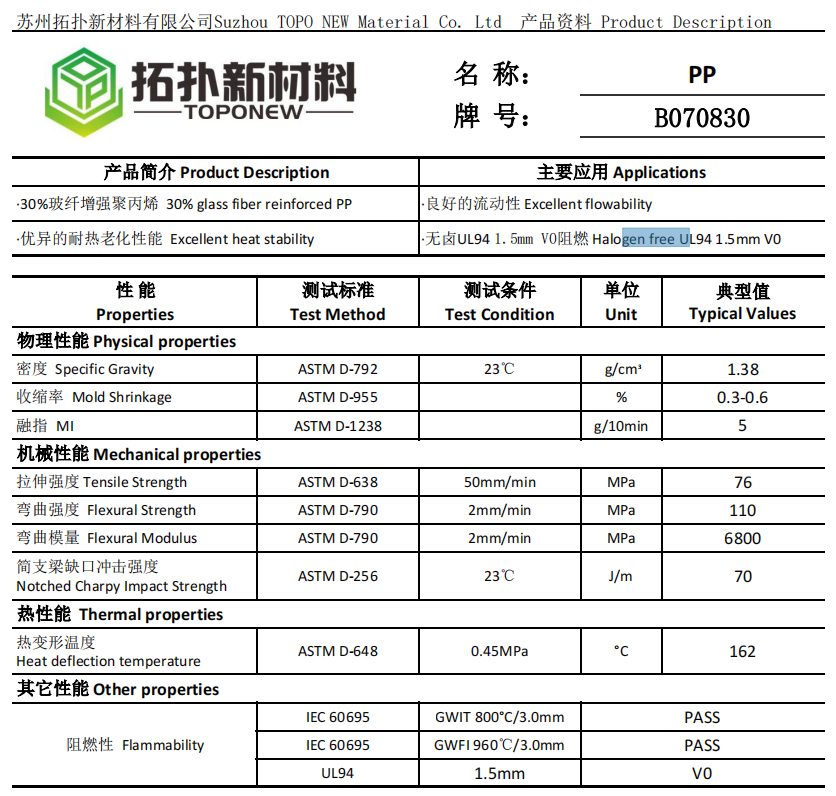

PP GF30 B070830

Glass Filled: 30%

Halogen Free

UL94 1.5mm V0

(Custom materials available according to your Technical Data Sheet)

- Информация о продукте

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PP GF30 B070830 Non-halogen Flame Retardant Material

Our PP GF30 B070830 is a type of halogen-free flame retardant plastic pellet that meets the UL94 1.5mm V0 flame retardant requirement. It has been tested and certified by SGS, REACH, and other organizations. This material combines the characteristics and advantages of PP with the enhanced performance of 30% glass fiber reinforcement.

Here are the key features of the PP GF30 Halogen-free material:

Low smoke generation: Produces minimal smoke and does not emit toxic or corrosive gases during combustion.

Halogen-free: Chlorine and bromine content each less than or equal to 500 ppm, total content less than or equal to 1000 ppm.

Environmentally friendly: Certified by UL in the U.S. and complies with regulations such as RoHS, SVHC, PFOS & PFOA, 17P, PAHs, etc.

Low density: At least 20% lower density compared to halogen flame retardant PP of the same type, offering a higher cost-performance ratio.

PP GF 30 stands for Polypropylene Glass Fiber 30. It is a type of composite material where polypropylene (PP) is reinforced with 30% glass fibers. This type of material is known for its improved mechanical properties compared to standard polypropylene, such as increased strength, stiffness, and temperature resistance. PP GF 30 is commonly used in automotive components, consumer goods, and industrial applications where increased durability and performance are required.

30% glass filled polypropylene, often denoted as PP GF 30, is a type of composite material made by incorporating 30% by weight of glass fibers into a polypropylene matrix. This blend results in a material that combines the properties of polypropylene with the added benefits of glass fibers, such as increased strength, stiffness, and resistance to heat and chemicals.

30% glass filled polypropylene is used in various industries for parts and components that require enhanced mechanical properties, dimensional stability, and performance under demanding conditions. Common applications include automotive parts, electrical components, appliances, and consumer goods.

PP GF30 can typically withstand temperatures up to 120-150°C (248-302°F) for short periods and maintain its mechanical properties. However, prolonged exposure to high temperatures can lead to degradation of the material and reduction in its mechanical properties.

It is always recommended to check the specific datasheet or technical specifications provided by the manufacturer for the exact temperature resistance of the PP GF30 material you are using.

The density of Polypropylene (PP) with 30% glass fiber reinforcement (PP GF30) can vary slightly depending on the exact composition and manufacturing process. However, a common density range for PP GF30 is around 1,350-1,450 kg/m³.

For more precise information, it is recommended to refer to the technical datasheet or specifications provided by the manufacturer of the PP GF30 material you are using.

Download

-

PP B070830.pdf

Download PP B070830.pdf